Center Pinning

Creating a solid foundation for movement, with proper frictionIt is impossible to finely regulate a piano that is poorly pinned. It takes a skilled hand and an excellent system to get superior results every time. Learn how to properly pin each center, and tricks to decrease your time so that this ceases to be a burden, and becomes something that separates you from the competition.

Table of contents

Chapter 1 - Proper friction management and measurement

- A: Friction parameters: What is “ideal” for each center, and why?

- B: A simple touchweight formula to reveal friction problems

- C: How to measure friction in each part: Tools and techniques

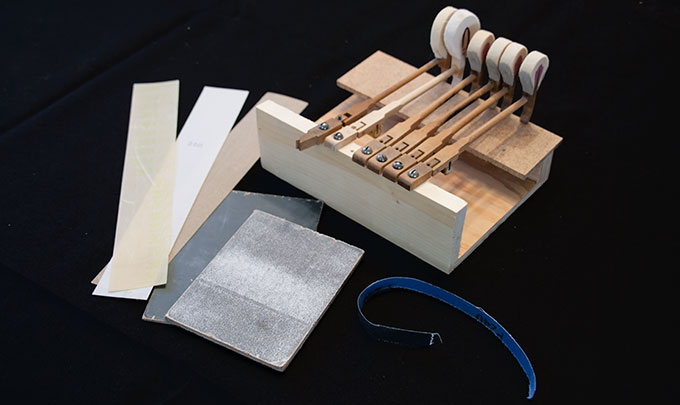

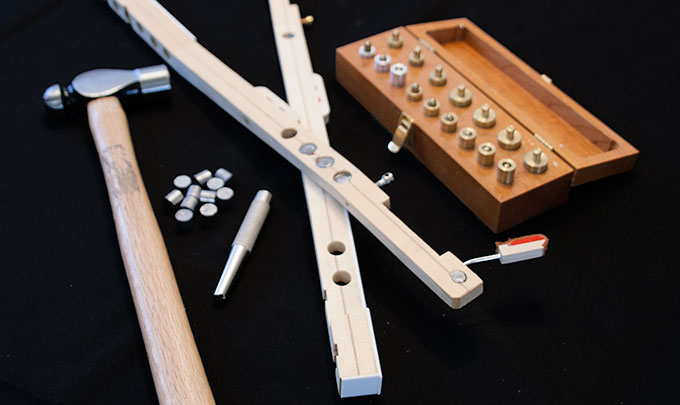

- D: Pinning 101: Using the correct tools with efficient methods

- E: DO NOT lubricate as a first resort!

Chapter 2 - Grand hammer rail repinning

- A: 10 ways to quickly detect hammer center pinning problems

- B: “It’s NOT the rep springs!” (Aka: Flyaway hammers in arid climates)

- C: Remedial work in the home: Finding and fixing the worst ones

- D: Temporarily “making it work” when you’re pressed for time (Before a concert)

- E: Doing the whole job: Uniform and consistent pinning

- F: Shortcut methods for institutional work

Chapter 3 - Repinning the jack center

- A: Symptoms of problems

- B: Measuring the friction

- C: Don’t forget to replace the rep spring!

Chapter 4 - Repinning the wippen flange center

- A: Symptoms of problems

- B: Measuring the friction

- C: Check wippen travel and alignment if you repin

Chapter 5 - Repinning the wippen rep lever center

- A: Immobilizing the rep lever spring

- B: Measuring the friction

- C: Check jack alignment in the window. Realign if necessary

Chapter 6 - Grand underlever repinning

- A: Why you will always get calls back if you don’t do it right

- B: Diagnosing problems: Checking both centers

- C: Check key bushings, damper guide rail friction, and overall friction

- D: Using “sizing fluid”

Chapter 7 - Vertical hammer flange repinning

- A: Diagnosing problems and measuring friction

- B: A “sure method” for repinning upright hammer flanges

- C: Don’t forget to travel and space hammers, and burn flanges

Chapter 8 - Jack, wippen flange, and damper centers in vertical pianos

- A: Diagnosing problems and measuring friction

- B: Some tips and tricks