Damper Work

Simplified and codifiedDamper work takes more technical skill than almost anything else in piano servicing. By learning Jim’s damper method, in a short time you can develop the skills needed to overcome your fear of damper work. Don’t let this part of piano work be something that you try to avoid at all costs!

Purchase Now

Table of contents

Chapter 1: Getting Started

- Introduction

- Two Main Objectives in Damper Work

- Getting Started

- Different Approaches, and Why I Do What I Do

- Summary

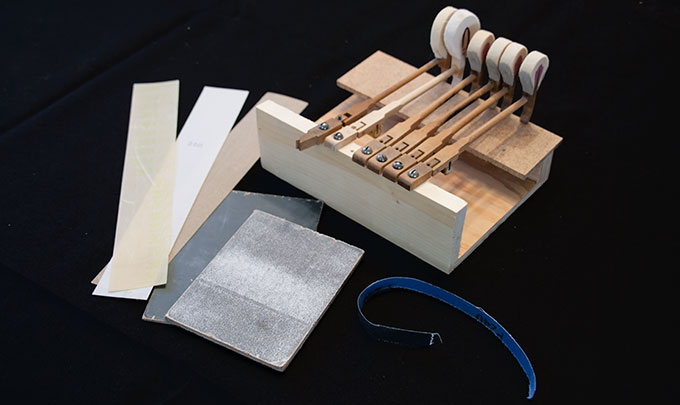

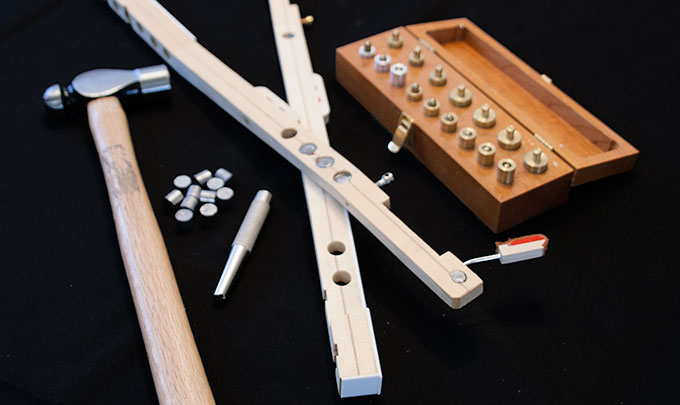

Chapter 2: Tools and Supplies

- A Few Words About Tools

- First Priority

- Second Priority

- Other Tools and Supplies

- Summary

Chapter 3: Naming the Bends/Using the Tools

- Naming the Four Bends

- Three Important Things to Remember

- Developing a Damper Man’s Eye

- Understanding and Making the Ten Essential Adjustments

- Summary

Chapter 4: Fine Damper Regulation

- The Pitch Raise Method

- The Nitpick Method

- An Order for Fine Tuning the Regulation

- A Final Checklist

- Summary

Chapter 5: In-The-Home Remedial Work

- Educating Clients

- Fixing Individual Leaking Dampers

- Adjusting the Pedals

- Individual Felt Replacements

- Going Beyond the Original Design

- Sticky Underlever Centers

- Summary

Chapter 6: The Back Action

- Crossing the “Magic Line”

- Checking/Changing the Damper Tray Pivot Blocks

- Making New Pivot Blocks

- Checking Friction in the System

- Setting the Damper Upstop Rail Height

- Replacing the Damper Upstop Rail Felt

- Replacing the Damper Tray Felt

- Summary

Chapter 7: Re-setting Damper Lift/Setting Tray Height

- Damper Lift from the Key Using Spoons

- Damper Lift from the Key Using Capstans

- Damper Lift Adjustments When There are No Spoons, Capstans, etc.

- A Protocol for Resetting All the Dampers

- Additional Notes

- Summary

Chapter 8: Replacing Damper Felt

- All Felt is Not Created Equal

- Removing Old Felt

- Installing New Felt

- Single Felt Replacement

- Summary

Chapter 9: Replacing Damper Wires

- Using New Wires with Old Heads/Hole Repair

- Replacing the Heads (New Set)

- Installing New Wires into New Heads

- Making the Initial Bends/Rough Installation

- Those Difficult Cantilevered Dampers!

- Summary

Chapter 10: Replacing the Back Action with a New Renner System

- The Renner Back Action

- Instructions Online

- Ordering the Right System

- Tips Beyond the Renner Instructions

- Summary

Chapter 11: Troubleshooting, Tricks of the Trade, and Miscellaneous

- Revisiting the Damper Man’s Eye

- Adding Weight to Dampers

- Softening the Felt: Oinking and Whooshing Dampers

- “Trimming the Beard”

- Thinning Bass Damper Felt

- Replace it!

- Pedals Revisited

- Replacing Key-End Felt

- Summary

Chapter 12: Upright (Vertical) Piano Dampers

- A Few Basics of Upright Dampers

- Replacing Damper Felt in an Upright Piano

- A Few Extra Tips

- Troubleshooting Upright Dampers

- Summary